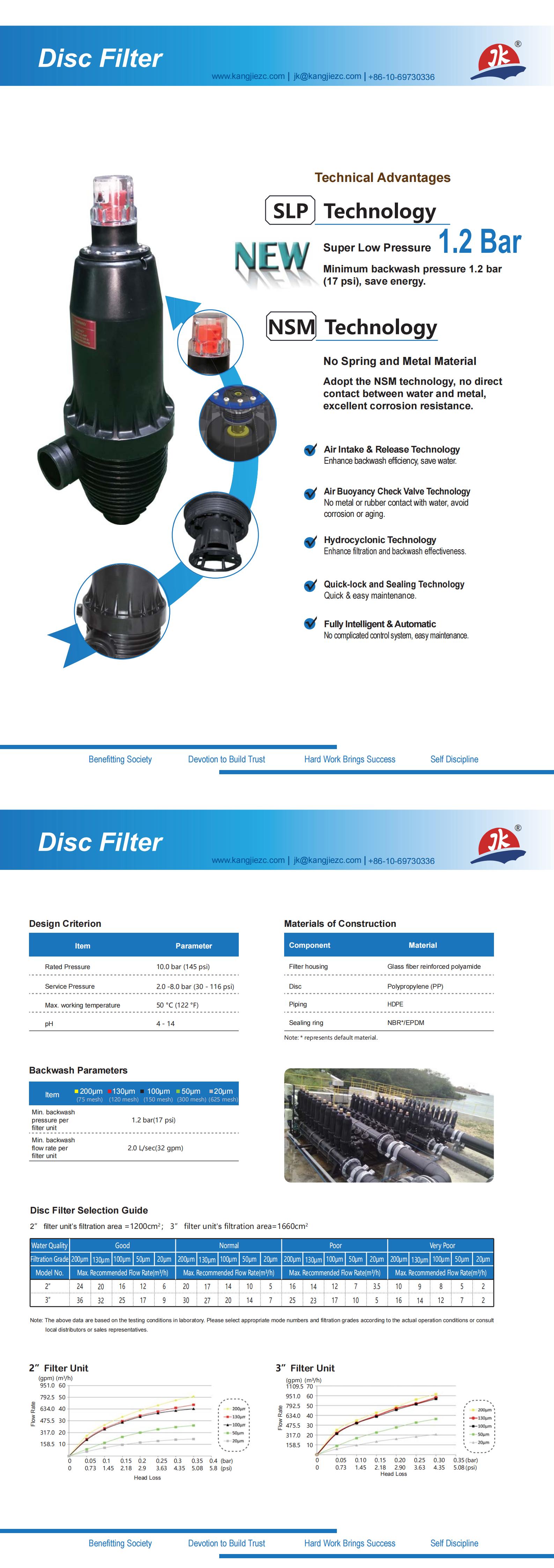

Automatic Back Flush Water Disc Filter for Cooling Tower/Irrigation/Sea Water Desalination System Pretreatment

Double row layout series disc filter system:

3 inch disc filter unit equipped with 3 inch backwash valve

This system can be equipped with 12 to 24 number of disc filter units

Filtration grade: 20-200μm

Pipping material: PE

Pressure: 2-8 bar

Pipping dimension: 8”-10”

Max. FR: 900m³/h

Technical features:

1. The filter unit adopts a unique “no spring” design, which has a strong corrosion resistance effect. The spring is a key component to ensure the operation of the stacked discs. By eliminating the pressure spring, the backwash pressure requirement of the disc filter is greatly reduced, saving energy. The backwash operation pressure is low, and there is no need for pressure reducing device, it can be directly connected to ultrafiltration. Backwash is as low as 0.15mpa, while other manufacturers on the market are ≥0.28mpa.

2. The whole machine is made of plastic, and the pipelines are welded by HDPE hot melt. This fundamentally solves the anti-corrosion problem for seawater desalination (rather than trying to prevent corrosion by various means).

3. Equipped with a large flow intake/exhaust device, each unit is equipped with an intake/exhaust valve, which avoids water hammer during filtration and increases the filtration area, and greatly improves the backwash effect during backwash. At the same time, the red float has an indication function of operation status.

4. The filter adopts a self-locking buckle combined with a specially designed sealing ring, which is made of all-plastic material and has strong corrosion resistance.

5. Cleverly using the buoyancy one-way valve design, the buoyancy principle is used to close the one-way valve during backwash, and the injection molding is integrated with good sealing effect, eliminating safety hazards of metal or rubber products.

Filter equipment structure:

A. Filter unit: the core of the filtration equipment, intercepts particles larger than the filtration accuracy in the feed water, and can be automatically backwashed.

B. Inlet pipeline: pipeline for feed water inlet.

C. Outlet pipeline: pipeline for filtered water outlet.

D. Sewage discharge pipeline: pipeline for sewage discharge during automatic backwash of the equipment.

E. Two-position three-way valve (backwash valve): a three-way diaphragm valve with changeable path, which is the key component for the equipment to realize automatic backwash process.

F. JFC controller: the control core of the filtration equipment (with built-in differential pressure sensor).